We’d like to remind Forumites to please avoid political debate on the Forum.

This is to keep it a safe and useful space for MoneySaving discussions. Threads that are – or become – political in nature may be removed in line with the Forum’s rules. Thank you for your understanding.

📨 Have you signed up to the Forum's new Email Digest yet? Get a selection of trending threads sent straight to your inbox daily, weekly or monthly!

The Forum now has a brand new text editor, adding a bunch of handy features to use when creating posts. Read more in our how-to guide

Low pressure in heating system

Albermarle

Posts: 30,437 Forumite

A family member has just moved to a house with an old unvented heating/hot water system, with an old boiler. I would not be surprised it was 30 years old as that is when the loft extension was done.

First ( and easy) issue is that the hot water was only warm from the taps as it was only set to 40 degrees, so I have turned up the stat to 60, and advised them to run the showers etc for a few minutes in case of any bugs in the system. The boiler and pump kicked in when I did that, so all seems OK.

The other issue I noticed is that the pressure in the system was very low - around 0.2 bar, so I tried to top it up but the valve is stuck.

I know a modern boiler will cut out if the pressure drops too low ( < 1 bar ?) but maybe a very old one ( non condensing one ) will not ?

If that is the case will the low pressure be damaging to the boiler in some way, even if it is working?

First ( and easy) issue is that the hot water was only warm from the taps as it was only set to 40 degrees, so I have turned up the stat to 60, and advised them to run the showers etc for a few minutes in case of any bugs in the system. The boiler and pump kicked in when I did that, so all seems OK.

The other issue I noticed is that the pressure in the system was very low - around 0.2 bar, so I tried to top it up but the valve is stuck.

I know a modern boiler will cut out if the pressure drops too low ( < 1 bar ?) but maybe a very old one ( non condensing one ) will not ?

If that is the case will the low pressure be damaging to the boiler in some way, even if it is working?

0

Comments

-

Make and model of boiler? Pic of the gauge?Assuming that 'pressure' = 'water', then clearly a lack of water with the boiler still running is not good news. The boiler itself should have an overheat 'stat inside it, but on a ~30-year old jobbie, who knows if it's working...I'd tentatively suggest, tho', that provided the 0.2bar is genuine - it is at that pressure - then they should be ok continuing to use it, but should monitor that pressure very carefully.What are their plans? If they need to keep it running for a year or so - say over the next winter - then it's pretty straight-forward to fit an external filling loop, and that would surely be worth doing? And you are more than capable...

0

0 -

I saw an unfamiliar name on the boiler, but have now forgotten what it was but will find out.( they only just moved in this afternoon

) It is a relatively compact one fitted sideways on in a cupboard, so difficult to access easily. The only controls seem to be on /off and a knob for the flow temperature

) It is a relatively compact one fitted sideways on in a cupboard, so difficult to access easily. The only controls seem to be on /off and a knob for the flow temperature

The gauge is a standard pressure gauge.

There is a filling loop but the valve is stuck, and the house has been mainly empty, so I guess the pressure has just slowly dropped off and not been topped up for ages. Obviously this valve needs unsticking, but I just wondered in the meantime, if the low pressure is such a big issue or not.

Most likely will have to have a new boiler soon enough, but as we often say on this forum, if the boiler is working just let it run until it stops.1 -

Absolutely. Keep it going!Albermarle said:I saw an unfamiliar name on the boiler, but have now forgotten what it was but will find out.( they only just moved in this afternoon ) It is a relatively compact one fitted sideways on in a cupboard, so difficult to access easily. The only controls seem to be on /off and a knob for the flow temperature

) It is a relatively compact one fitted sideways on in a cupboard, so difficult to access easily. The only controls seem to be on /off and a knob for the flow temperature

The gauge is a standard pressure gauge.

There is a filling loop but the valve is stuck, and the house has been mainly empty, so I guess the pressure has just slowly dropped off and not been topped up for ages. Obviously this valve needs unsticking, but I just wondered in the meantime, if the low pressure is such a big issue or not.

Most likely will have to have a new boiler soon enough, but as we often say on this forum, if the boiler is working just let it run until it stops.

Do you know if they asked the vendors to give it a service before sale?

Anyhoo, if it runs ok at 0.2bar, then all good. Just keep an eye :-)

0 -

Have now had a better look at the boiler .

It is a Potterton Suprima ( 602? ).

From a quick google, it is probably about 25 years old ( not 35) and has been serviced.

It is working and heating the hot water up, so probably best left well alone.

The pressure in the system remains very low though, and they will ideally have to get that jammed filling loop valve opened at some point to top it up.

Looking at the old unvented tank and the old radiators, I suspect when the boiler does eventually need replacing they would be wise to look at a wider upgrade.1 -

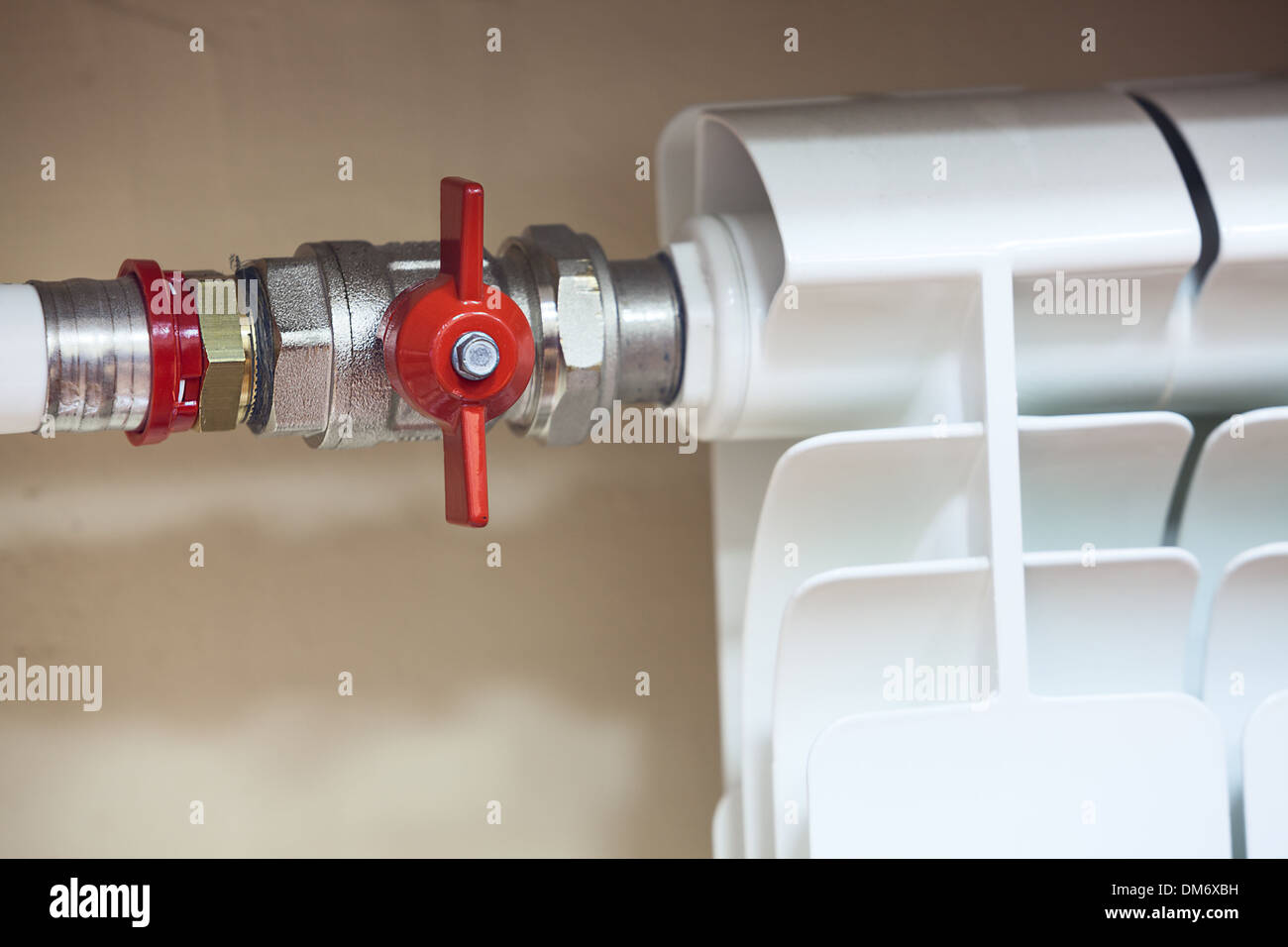

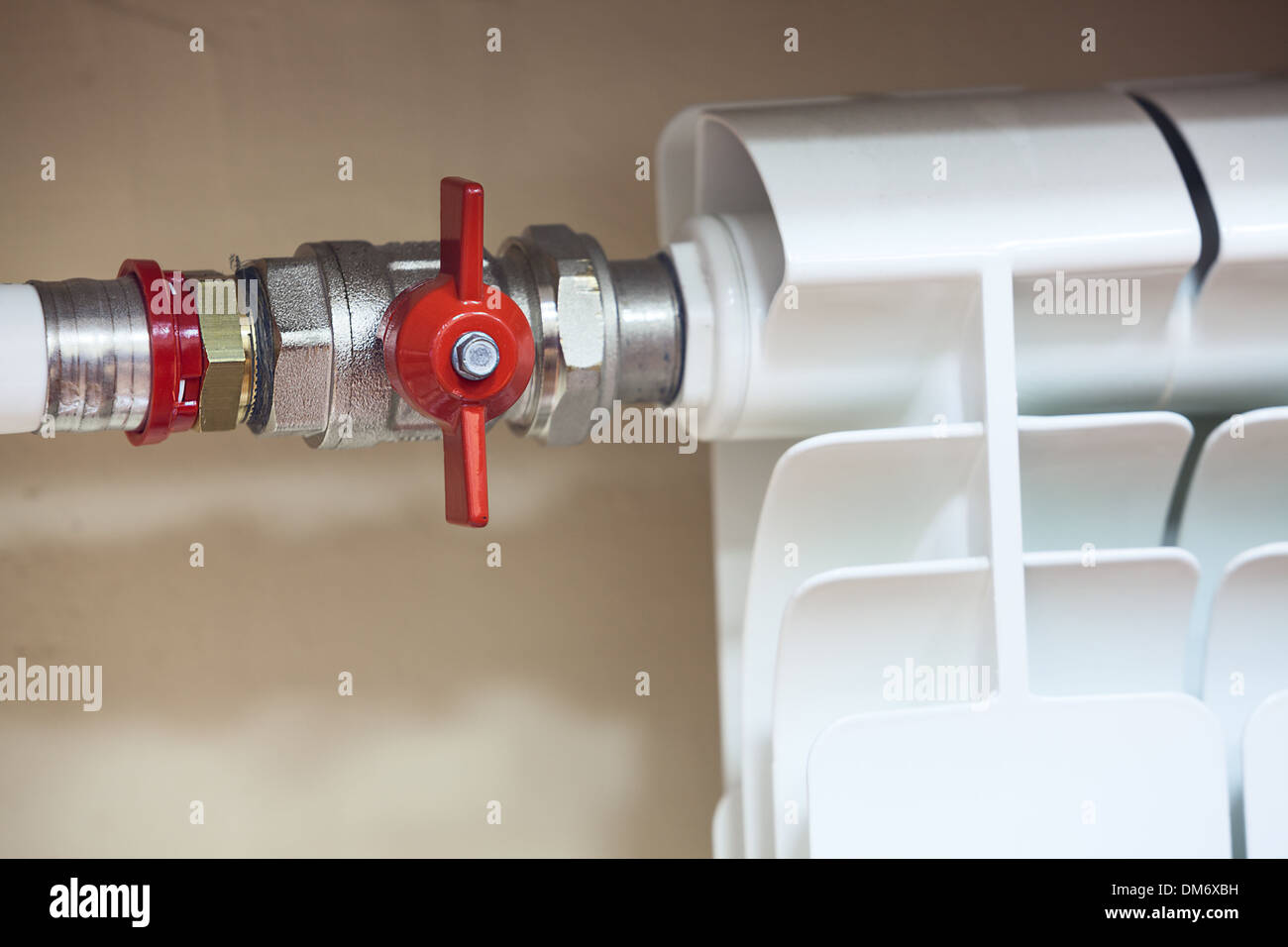

Next time you visit, could you take pics of the filling valve, please? See if there's an obvious connecting pipe, and a valve on each end.Does it look like this: https://www.acwilgar.co.uk/Boiler-Manual-PDF/Potterton/POTTERTON SUPRIMA 30,40,50,60,70,80.pdf ?That boiler is designed for both vented and unvented use, with an expansion vessel and pressure gauge being added for the latter. Since it's designed for vented use, then a low operating pressure of 0.3bar would not be unusual, so I'm not surprised it works ok. It seems, tho', that it should be pressurised to above 1 bar for unvented use, but as long as they keep an eye on it, and get the top-up valve sorted (or even just add a simple filling loop) at some point, they should be fine.But keep an eye on the gauge!

0 -

Yes it is one of those, thanks for the manual link , I will save it.WIAWSNB said:Next time you visit, could you take pics of the filling valve, please? See if there's an obvious connecting pipe, and a valve on each end.Does it look like this: https://www.acwilgar.co.uk/Boiler-Manual-PDF/Potterton/POTTERTON SUPRIMA 30,40,50,60,70,80.pdf ?That boiler is designed for both vented and unvented use, with an expansion vessel and pressure gauge being added for the latter. Since it's designed for vented use, then a low operating pressure of 0.3bar would not be unusual, so I'm not surprised it works ok. It seems, tho', that it should be pressurised to above 1 bar for unvented use, but as long as they keep an eye on it, and get the top-up valve sorted (or even just add a simple filling loop) at some point, they should be fine.But keep an eye on the gauge!

There is an obvious connecting/top up pipe with a valve at each end, the valves look like the one in the image except the grip is black plastic. One will turn so it is parallel with the pipe, but the other is stuck.

I am tempted to try and force it with a wrench but hesitating.

1 -

Would a spray of WD40 release it? I’ve no idea if it could cause more problems but I tend to revert to wd40 for most problems.0

-

Albermarle said:Yes it is one of those, thanks for the manual link , I will save it.

There is an obvious connecting/top up pipe with a valve at each end, the valves look like the one in the image except the grip is black plastic. One will turn so it is parallel with the pipe, but the other is stuck.

I am tempted to try and force it with a wrench but hesitating. A photo would still help, but the main problem with plastic handles, as I'm sure you know, is that they can mangle :-)However, since you have the - correct - two valves, and one is seemingly working ok, there is little actual risk in trying to 'oblige' the other one to move; as long as the other one is closed, what can go wrong?! :-)So, if the plastic handle can easily come off - a central screw or nut - then by all means try a wee adjustable spanner on the shaft. The other valve will be shut during this, so no risk of being wetted...It will almost certainly move - a sudden release - and will then be fine. Jobbie jobbed, and you are a plumbing hero.But don't come to me if you flood their new home...0

A photo would still help, but the main problem with plastic handles, as I'm sure you know, is that they can mangle :-)However, since you have the - correct - two valves, and one is seemingly working ok, there is little actual risk in trying to 'oblige' the other one to move; as long as the other one is closed, what can go wrong?! :-)So, if the plastic handle can easily come off - a central screw or nut - then by all means try a wee adjustable spanner on the shaft. The other valve will be shut during this, so no risk of being wetted...It will almost certainly move - a sudden release - and will then be fine. Jobbie jobbed, and you are a plumbing hero.But don't come to me if you flood their new home...0 -

WD40 is a water dispersant and general purpose lubricant. It can degrade certain rubbers used in seals. What it is not is a penetrating oil, so on seized nuts/bolts & shafts, it is not particularly effective. Something like PlusGas would be more suitable (still need to be careful with some types of rubbers).OutdoorQueen said:Would a spray of WD40 release it? I’ve no idea if it could cause more problems but I tend to revert to wd40 for most problems.

Any language construct that forces such insanity in this case should be abandoned without regrets. –

Erik Aronesty, 2014

Treasure the moments that you have. Savour them for as long as you can for they will never come back again.0 -

Before you remove the plastic handle, look at it carefully, and it will likely show it can only be turned one way. Once removed, the chances are the shaft can be turned either way, and actually rotated ad infinitum - it'll almost certainly be a 'ball' valve inside. So, try turning it the 'correct' way first with your spanner, but you should be fine trying it either way.

With the handle off, look for signs of scale on the shaft, which would indicate it's weeping slightly and this scale might be why it's reluctant to turn. Wipe/brush any off.

But almost certainly it will release and then turn smoothly given enough 'force'. Hold the valve firmly in one hand, and turn t'spanner with t'other.

A very good way to apply strong pressure in a 'controlled' manner is to try the spanner or wrench on the spindle in a number of directions, until you find one that has the spanner handle in a similar direction to the actual pipe, but not quite in line. Do this so that to then turn the spanner to be fully in line would be to turn the shaft in the desired direction. Make sense?!

Ok, now grasp the pipe and spanner in one clenching hand, adding the other hand over it if needed, and just squeeeeeze to turn.0

Confirm your email address to Create Threads and Reply

Categories

- All Categories

- 353.5K Banking & Borrowing

- 254.2K Reduce Debt & Boost Income

- 455.1K Spending & Discounts

- 246.6K Work, Benefits & Business

- 603K Mortgages, Homes & Bills

- 178.1K Life & Family

- 260.6K Travel & Transport

- 1.5M Hobbies & Leisure

- 16K Discuss & Feedback

- 37.7K Read-Only Boards